Industries Detail-Heath Care

Why is Custom Packaging Essential for Small Medical Devices?

Customizing packaging boxes for small medical and health devices is essential because it provides tailored protection that safeguards delicate instruments like portable blood pressure monitors, glucose meters, and pulse oximeters during transport and storage. Custom packaging ensures ease of access, allowing healthcare professionals and consumers to retrieve and store devices efficiently. Additionally, it enhances brand identity and professionalism by incorporating logos, instructional graphics, and product information directly on the custom medical packaging box. This not only educates users on proper device usage but also reassures them of the product’s quality and reliability. By meeting regulatory standards and enhancing the overall user experience, custom medical device packaging box ultimately leads to greater customer satisfaction and trust.

Custom Healthcare Packaging to Strengthen Brand Identity

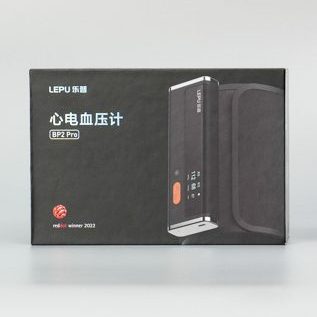

Custom packaging boxes for small medical and health devices play a crucial role in establishing and reinforcing a brand’s identity and professional image. They differentiate your brand with unique logos, colors, and designs, making your products instantly recognizable and memorable. For example, a portable blood pressure monitor packaged in a box that features your brand’s signature colors and logo, along with clear instructional graphics, immediately conveys professionalism and trustworthiness.

Superior Protection with MJC’s Custom Boxes for Medical Devices

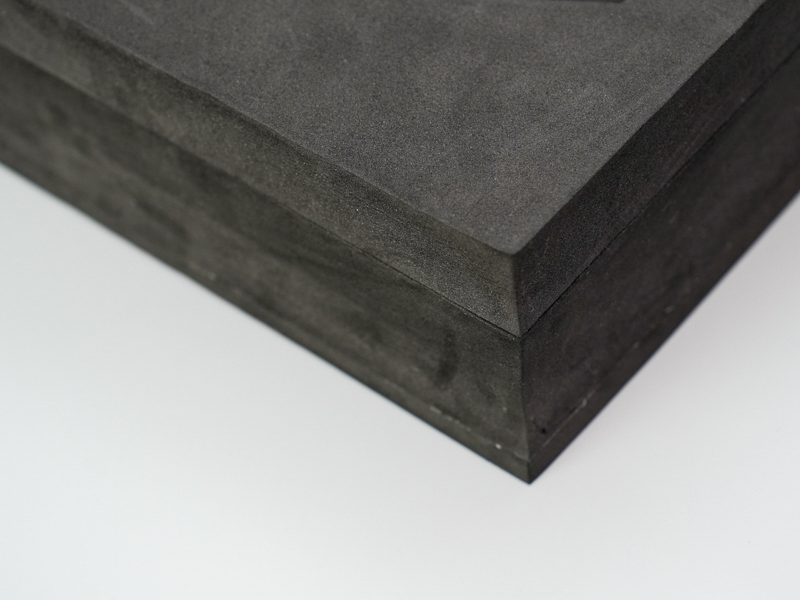

The custom rigid medical device boxes from MJC Packaging provide exceptional physical protection, making them ideal for packaging small, delicate, and expensive medical devices. These boxes are designed to withstand significant external pressures, thereby minimizing the risk of damage during transportation and storage. The robust construction effectively absorbs and dissipates shocks and impacts, ensuring that sensitive medical equipment remains secure and intact throughout the logistics process. For precision instruments and high-value medical devices, the sturdy nature of rigid boxes is particularly beneficial, as it significantly reduces the likelihood of vibrations and impacts affecting the integrity and functionality of the equipment. This level of protection is crucial in maintaining the reliability and safety of medical devices, ensuring they reach the end-user in perfect condition.

Enhancing User Education with Custom Medical Packaging

Professionally designed packaging signals quality and attention to detail, instilling trust and credibility in customers while offering a consistent look across all product lines. Incorporating customized booklets, instructional graphics, product certifications, and personalized messages like “Your Partner in Health” or customer names creates a cohesive brand image that tells your brand’s story and values, emphasizing your commitment to innovation and care while enhancing your reputation in the industry.

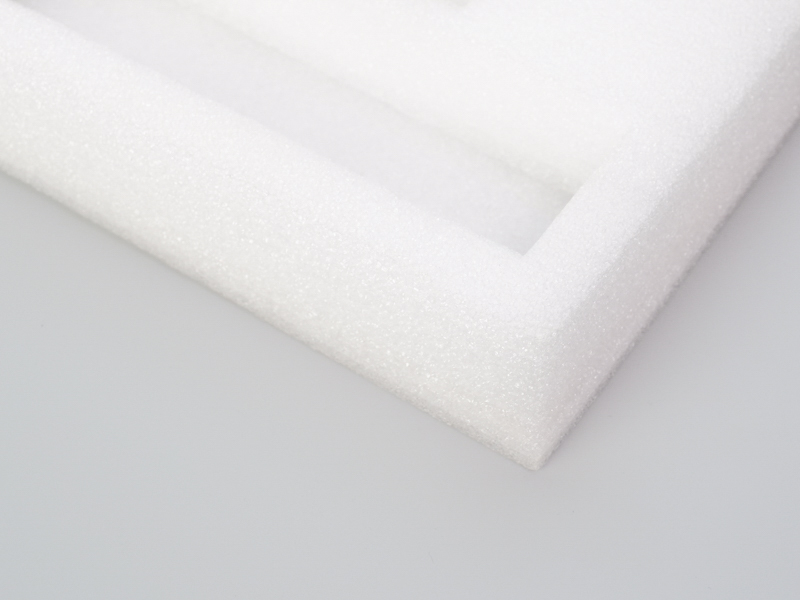

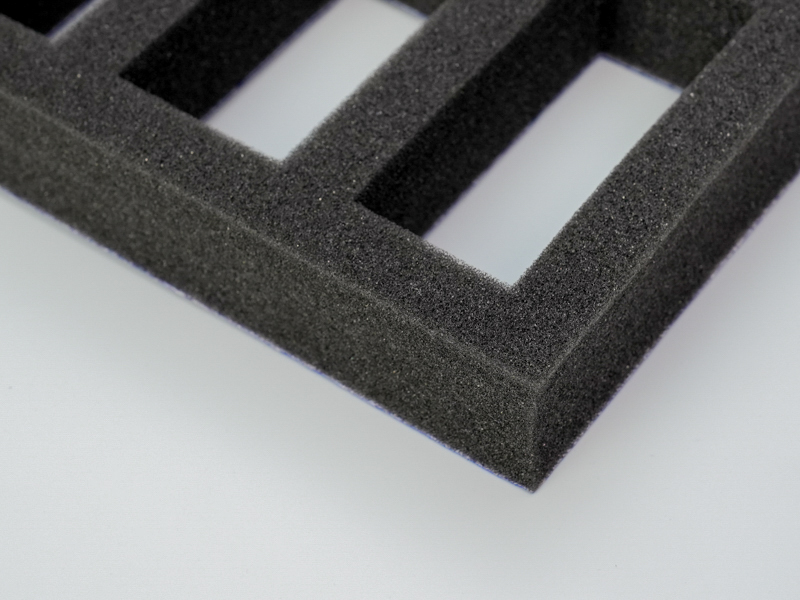

The Importance of Custom Inserts for Medical Device Packaging

Custom inserts for compact medical device packaging are required for a variety of reasons. They keep the equipment safe within the box, decreasing the impact of shocks and vibrations during travel, which is critical for delicate and precision instruments. Custom inserts also improve product presentation and user experience by making the gadget easy to remove and restore to its original position, increasing convenience and satisfaction. Furthermore, specialized inserts meet the specific safety and cleanliness requirements for medical equipment throughout transportation and sale. They can also be used as a marketing tool, with the ability to display company logos or promotional messages that reinforce brand identification and create a lasting impact on customers.

Full Options from Custom Medical Device Packaging Boxes Supplier

MJC Packaging specializes in customizing professional medical packaging solutions tailored specifically for clients in the medical and healthcare device industry.

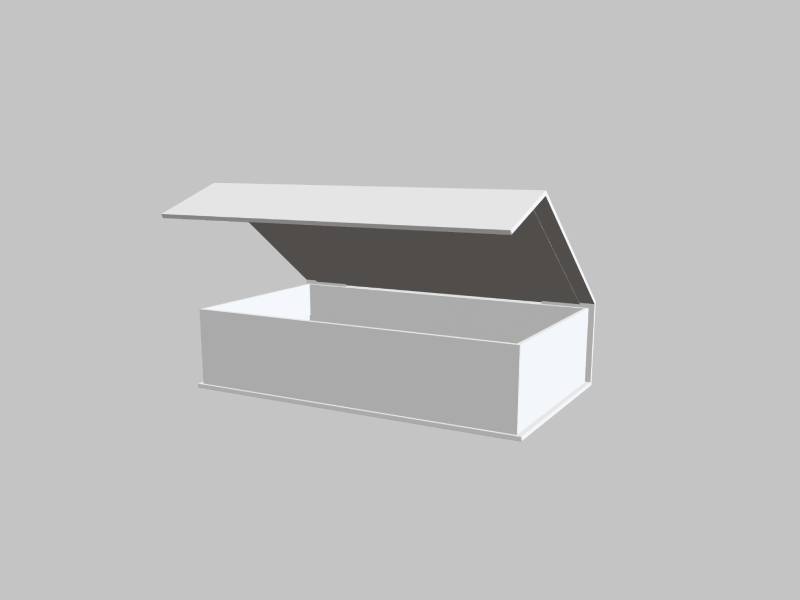

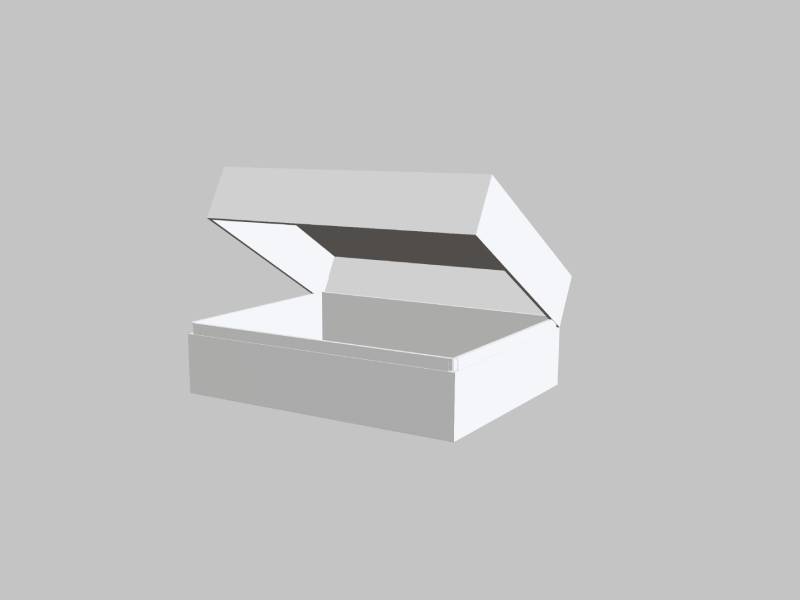

【Magnetic Box】

Custom magnetic jewelry packaging box has an elegant design, secure closure, and a captivating unboxing experience for your cherished and fashionable jewelry.

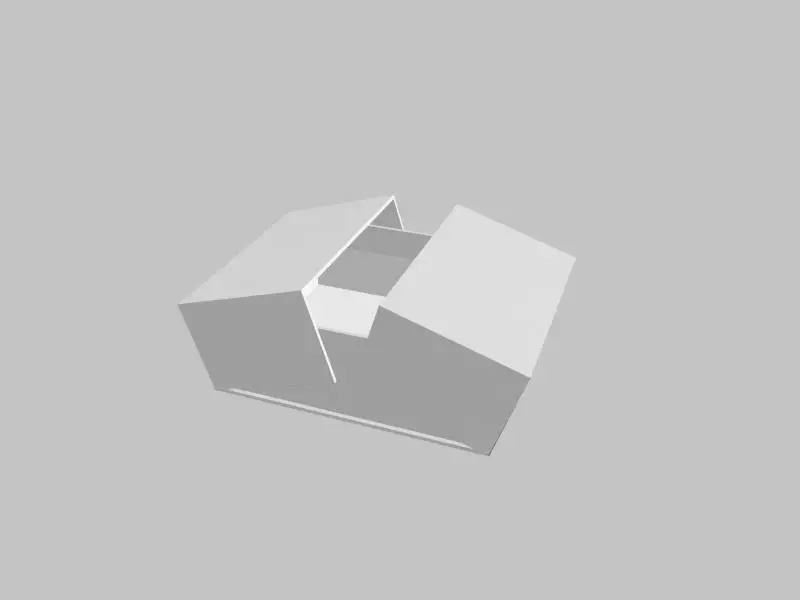

【Lid and Base Box】

【Drawer Box】

【Shoulder Neck】

【Paper Tube】

With easy-to-open end caps or pull tabs, paper tube packaging ensures a user-friendly and enjoyable unboxing experience for customers.

【Double Door Open】

【Handle Box】

【Hinged Flip Lid】

In this jewelry packaging, we usually attach a metal lock to the box to lock it down. This paper box costs less than a wooden box but has the same effect as a wooden one.

【C1S】

【C2S】

【CCNB】

【Kraft Paper】

【Corrugated Board】

【Special Paper】

【Grey Chipboard】

【Duplex Chipboard】

【Offset Print】

【Digital Print】

【UV Print】

【Ink Print】

【Pantone-Based Print】

【Aqueous Costing】

Clear, fast-drying, water-based, and eco-friendly coating. Available in gloss or matte finish.

【UV Coating】

Fast-drying coating cured with ultraviolet light. Available in gloss or matte finish.

【Spot Gloss UV】

UV coating that is applied to a specified area and cured using ultraviolet light.

【Soft Touch Coating】

Soft to the touch coating that creates a velvety texture for a more tactile appeal.

【Varnish】

Clear coating applied using the CMYK printing method. Available in gloss, satin, or matte.

【Lamination】

Laminated protective film that adheres to the surface of packaging materials to maximize durability.

【Anti-scratch Lamination】

Laminated BOPP film that is scratch, scuff, and fingerprint resistant. Cost-effective option.

【Soft Touch/Silk Laminations】

Soft to the touch lamination similar to peach skin. Available in a satin or matte finish.

【Fabric & Paper Bags】

【Stickers】

【Thank-You Cards】

【Logistics Boxes】

【EVA】

【EPE】

【PU】

Title Name

Text

Title Name

Text

Title Name

Text

Title Name

Text

Title Name

Text

Title Name

Text

Title Name

Text

Title Name

Text

Title Name

What Types of Packaging Boxes Are Best Suited for Small Medical or Healthcare Devices?

For packaging small medical or healthcare devices, the most suitable types of packaging boxes are typically rigid or semi-rigid containers that offer a blend of protection, visibility, and ease of use. Here are some examples:

Thermoformed Plastic Trays: These trays are custom-molded to fit the specific shape of the device, providing excellent protection against physical damage while maintaining a lightweight profile. They are often used in combination with a clear plastic cover or a sealed pouch, allowing visibility of the product without opening the package. For instance, dental retainers or hearing aids are commonly packaged in these trays to keep them secure and sterile.

Blister Packs: Blister packaging is ideal for small healthcare devices due to its compact nature and the ability to combine a rigid plastic cavity with the backing of paperboard or foil. This type of packaging is excellent for single-use items like diabetic test strips or lancets, as it provides a sound barrier against moisture and contaminants and is easy to open.

Clamshell Packaging: Clamshell packs are made from a single piece of plastic that folds onto itself like a clamshell. This type is beneficial for slightly larger or irregularly shaped devices, such as handheld medical monitors or small diagnostic devices. They can be sealed to enhance tamper resistance and sterilization and are also accessible for consumers to open and reclose, which is handy for devices used repeatedly.

Rigid Boxes with Custom Inserts: For higher-end devices or those needing extra protection, a rigid box with custom foam or cardboard inserts can be used. The inserts keep the device in place, preventing movement and potential damage during shipping. This option is suitable for delicate instruments like portable ultrasound machines or advanced therapy devices.

These packaging options not only ensure that the device is protected from physical and environmental factors but also enhance the user experience by making the package easy to handle and open.

Our expertise is here to serve you

Explore excellence effortlessly! Feel free to request a quote—call, email, or submit a form. Our experienced packaging experts are ready to provide personalized 1v1 VIP service just for you.